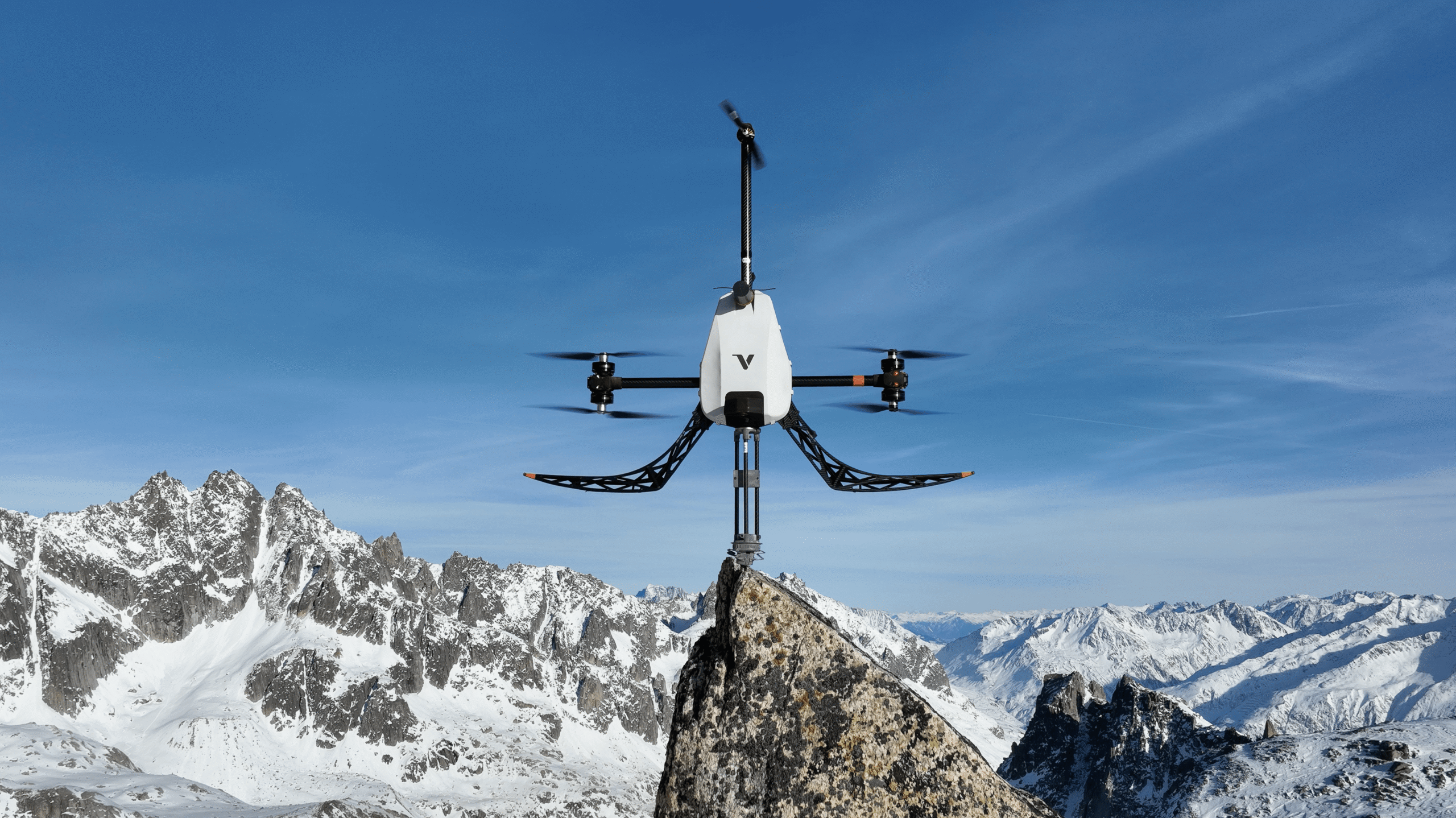

Voliro company

Advanced aerial robotics platforms for non-destructive testing and inspections, providing consistent accuracy and structural insight.

Voliro overview

Voliro is a pioneer in advanced aerial robotics, dedicated to redefining how industries conduct inspection, maintenance, and interaction with critical infrastructure. Built on years of rigorous research and field-proven innovation, the company develops flying robots capable not only of observing their environment but also of physically interacting with it — a capability that marks a transformative leap beyond traditional drone operations.

At the core of Voliro’s mission is the belief that assets at height should be inspected and maintained without exposing workers to unnecessary risk and without the costly disruption of industrial processes. By combining innovative engineering with practical field insight, Voliro delivers robotic solutions that extend asset lifecycles, enhance productivity, and significantly reduce operational downtime.

A Vision Rooted in Research and Innovation

Voliro’s technology originates from extensive research at the Autonomous Systems Lab (ASL) of ETH Zurich, one of the world’s leading robotics institutions. What started in 2016 as an ambitious academic exploration — building a fully omnidirectional flying robot capable of stable physical interaction — rapidly turned into a groundbreaking engineering achievement.

The company officially incorporated in 2019 with the support of Wyss Zurich, an accelerator known for backing high-impact, research-driven ventures. With this foundation, Voliro built a unique blend of robotics expertise, industrial understanding, and product-focused engineering discipline.

After years of development, rigorous testing, and collaboration with industry leaders across energy, construction, and heavy industry, Voliro launched its first commercial system. The response from the field was immediate: major global operators recognized its potential for safer, more efficient, and more comprehensive inspection workflows.

Expanding the Boundaries of Aerial Robotics

Traditional drones operate with a simple philosophy: fly and observe. Voliro transforms this model into fly, see, and touch. Its signature innovation — a tiltable rotor system enabling true 360° aerial mobility — gives operators unprecedented freedom to move, orient, and interact with industrial structures from any angle.

This omnidirectional capability allows the company’s flagship platform to apply controlled force, maintain stable contact, and perform non-destructive testing (NDT) at height or on complex geometries such as curved tanks, sloped surfaces, domes, and other challenging configurations. No other aerial inspection robot provides comparable dexterity, stability, and surface interaction.

Voliro’s technology delivers:

-

Stable Contact & Interaction: Ability to apply consistent force and torque during inspection tasks.

-

Full 360° Mobility: Free movement in all directions without orientation constraints.

-

Automated Flight Assistance: High levels of autonomy even in GPS-denied or cluttered environments.

-

Open, Versatile Platform: Support for multiple sensor payloads and specialized inspection tools.

These capabilities redefine what flying robots can contribute to industrial inspection workflows.

Driving Efficiency for Asset Owners and Service Providers

Voliro’s solutions create value throughout the inspection ecosystem — from asset owners seeking to maximize uptime to service providers delivering high-precision results under tight operational constraints.

For Asset Owners

-

Optimized Shutdown Planning: More tasks completed in the same window of time.

-

Early Fault Detection: Ability to inspect more frequently and proactively.

-

Reduced Downtime: Many inspections can now be carried out while assets remain in service.

-

Extended Asset Lifetimes: Improved monitoring leads to better long-term planning and reduced unexpected failures.

For Inspection Service Providers

-

Higher Productivity: Robots can accomplish complex inspections faster and more consistently.

-

Cost Reduction: Minimizes scaffolding, rope access, and other high-cost methods.

-

Technology Differentiation: Offers clients cutting-edge tools that outperform conventional solutions.

-

Portfolio Diversification: Enables expansion into new types of inspections and industrial segments.

Voliro’s technology is not simply a more efficient tool — it becomes a competitive advantage.

Commitment to Reliability, Safety, and Real-World Performance

Voliro builds platforms designed for demanding industrial environments — places where precision, robustness, and safety are non-negotiable. The company’s flying robots operate reliably around metal structures, confined spaces, and complex architectural geometries where GPS is unavailable and where unpredictable airflow is common.

Automated flight modes reduce pilot workload, ensuring consistent performance even during close-proximity operations. Stability during surface contact — one of the most challenging tasks in aerial robotics — is continuously maintained by a system of intelligent control algorithms and hardware design choices refined through thousands of test hours.

The platform’s modular architecture supports a broad range of industry-grade payloads. From advanced NDT sensors to lightning protection testing tools, Voliro enables inspection teams to complete tasks that would otherwise require cranes, elevated work platforms, or hazardous human access.

A Global Presence Backed by Industry Leaders

Since its early deployment phase in 2022, Voliro has collaborated with major industrial operators, including Shell, Petronas, and Holcim, validating the technology in some of the world’s most challenging operational environments.

By 2023, the system reached general availability, accelerating adoption across the global NDT ecosystem. Inspection leaders such as Mistras, Acuren, Team Inc., and many others have since integrated Voliro’s technology into their workflows, helping establish the platform as the new standard for aerial inspection and contact-based measurement.

Voliro continues to expand worldwide, bringing advanced robotic capabilities to industries seeking safer, more reliable, and more efficient inspection solutions.

Leading the Future of Aerial Mobile Robotics

Voliro’s mission is to elevate mobile robotics beyond observation and into meaningful interaction. The company is driven by a commitment to innovation, engineering excellence, and real-world problem-solving.

As infrastructure ages, industrial systems become more complex, and the need for safe, efficient inspection grows, Voliro stands at the forefront — offering technology that fundamentally evolves how maintenance and repair at height are performed.

With deep academic roots, a visionary engineering team, and a rapidly growing global customer base, Voliro is shaping the future of inspection robotics and setting a new benchmark for aerial interaction technology.

Voliro is not just building drones. It is redefining how humans and machines work together to protect, maintain, and sustain the world’s critical infrastructure.