Mining is critical for a steady supply of energy resources and rare earth metals for technological advancements. Yet, it’s also a tough business with enduring operating conditions, safety hazards, and stringent regulations.

Many operating processes require aerial visibility – drones in mining have become indispensable for land surveying, risk assessments, stockpile management, and an array of other use cases.

3 Use Cases of Drones in The Mining Industry

Since 2016, 70% of large mining companies have gone from using drones for fringe cases to fully integrating the technology into surveying, engineering, and monitoring workflows.

Learn how leaders are using drones to optimize operations, cut costs, and increase employee safety.

Streamlined Land Surveying

Mines need land surveying services constantly and in large quantities. Aerial monitoring ensures safe on-site operations, resource assessments, and expansion planning.

Traditional land survey methods like triangulation, tachymetry, chane and tape surveying are time-consuming and require a large on-foot workforce. Surveying personnel at an active mine can interfere with operating equipment, leading to costly downtime. Larger projects like pit-to-port road construction or new mineral exploitation require coverage of large distances.

Drones in mining are a more time- and cost-effective alternative to conventional land surveying methods. The best fixed-wing and quadcopters with a gas-electric powertrain can stay in the sky for several hours, covering 250-1000+ acres in one flight.

The selection of land-surveying drone payloads available is impressive: HD RGB, oblique, thermal, and multispectral cameras, LiDAR sensors with centimeter-level positioning accuracy, magnetometers, and photogrammetric cameras. Thanks to advances in aerial autonomous navigation, the best drones for mining now have automated data capture modes and can generate 3D environment maps for better situational awareness.

Roughly 83% of mining companies use drones for mapping and surveying, including the Baorixile Open Pit Mine. With a 50 square kilometer mining license area and 640 million tons of coal reserves, the mine is crucial for the local market. However, harsh environmental conditions — snow, sub-zero temperatures, icing — make land surveying missions challenging. Likewise, naturally occurring electromagnetic interference (EMI) hampered drone navigation, causing GPS signal loss and IMU instability. So instead of sending personnel, the operators switched to using Jouav CW-25E UAV with LiDAR technology.

The drone collected 125 times more data points per square meter than conventional RTK surveying, with under 5 cm accuracy. Data acquisition times were reduced from 13 days to 2 — a 6.5X increase in efficiency. Personnel no longer had to endure the harsh climate, controlling the drone from a parked vehicle.

Stockpile Management

Stockpile management is another labor-intensive task in mining operations. Accurate volume and mass calculations are challenging due to extreme heights and irregular shapes (which also change frequently). However, ensuring structural stability is crucial to prevent accidents. Stockpile collapses and nearly avoided accidents trigger regulatory investigations and fines.

With drones in mining, companies can produce aerial terrain models of their inventory and keep track of stockpile changes over time to ensure safe and effective operations. Ferrexpo Yeristovo Mine regularly employs drones to conduct land surveys, create up-to-date stockpile maps, and minimize risk to personnel.

DroneUA helped Yeristovo mine operators create a 3D model of an 82-hectare / 202-acre open pit, collecting data from 410 meters/1345 feet below ground. The team collected over 1,000 data points for 2D/3D models.

The second major project involved mapping an ore stockpile. The team created pre-planned navigation routes to automate data collection and ensure high data fidelity. Stockpiles occupy large areas with uneven terrain, making hand-held tools less effective. Drones, equipped with photogrammetric cameras, allow greater precision and keep personnel out of dangerous areas. In both cases, drone-led data collection took 90% less time than traditional methods.

Mineral Exploration

Drones in mining provide a new vantage point for exploring new mineral sites, as well as resource evaluation and subsequent excavation planning. Thanks to advanced onboard sensing technologies and specialized payloads (e.g., an echosounder, metal detector, magnetometer, etc), drones can be used to perform geological mapping missions at faster speeds. For example, identify ore bodies’ spatial distribution or detect tramp metal in stockpiles to prevent costly crusher outages during the excavation phase.

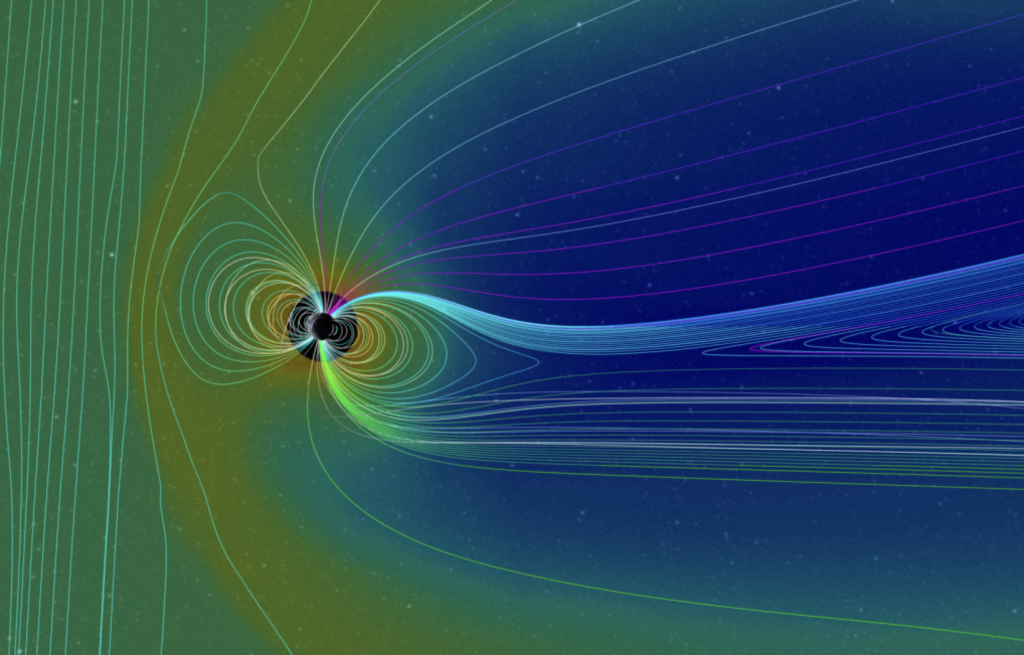

Yet, drone deployments on mining sites can be challenging due to high EMI levels. Some minerals (e.g., magnetite or pyrrhotite), as well as mining equipment like proximity sensors or high-voltage power cables, can interfere with the navigation systems. Bavovna developed an AI-driven hybrid navigation kit for VTOL, Fixed Wing, Multirotor, or Quad to safely cruise in high EMI environments. With Bavovna’s AI navigation kit drones can maintain 99% positional accuracy in high EMI/GPS-denied environments and reliably follow the original flight path despite the interferences. The navigation unit is housed in an EMI-protected box, attenuating interferences at 92dB per mm.

Unlike computer vision-based systems, which require substantial computing resources, Bavovna’s solution relies only on device sensor data, streamed into a lightweight AI model for fully autonomous operations.

Underground tunnel mapping is another labor-intensive task at new mining sites. Irregular tunnel shapes and confined spaces complicate equipment placement and safety. Physical obstructions and geological interferences render traditional surveying methods ineffective. High dust and low lighting limit the usage of optical surveying tools.

Confined space drones have emerged to address these challenges. Featuring a rugged, caged design and advanced obstacle detection, the best indoor drones can cruise through narrow passages and access restricted areas to collect mapping data. Elios 3 from Flyability uses LiDAR and computer vision technologies to generate real-time 3D-environment maps for piloting in GPS-denied environments.

Similar to above-ground land surveying, indoor drones create operational efficiencies and savings. At Glencore Kidd Mine in Ontario operators used Elios 3 to eliminate time-consuming drilling and expensive equipment movement. Within 15 minutes, the team inspects flagged areas and gains video footage and 3D maps of underground conditions.

Conclusion

The usage of drones in mining has grown at a massive clip over the years and for some good reasons. Aerial surveillance capabilities, coupled with a great array of payloads, help miners conduct faster site assessments, survey underground tunnels, and improve asset management lifecycles.

Thanks to advances in onboard sensing capabilities and new navigation technologies like Bavovna’s kit, drone flights have also become much safer even in GNSS-denied and tough environmental conditions, paving the way for even more deployment scenarios.